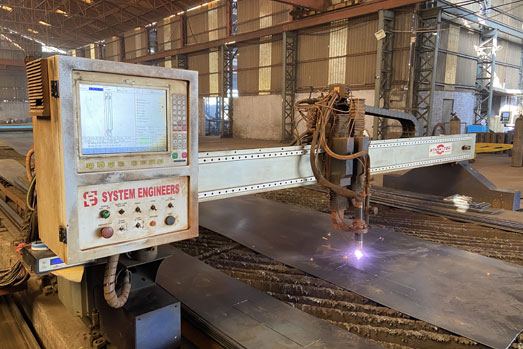

Paruthi Group holds pride in owning a huge 10-acre and 5-acre manufacturing facility. With 400k sq. ft. of shed area, Paruthi Group has a processed and chained system to feed the raw material. A total of 30 cranes are in use to ensure smooth and streamlined production.

Paruthi Group has mastered the art of prototype fabrication, inspection and approvals. After the first offer of examination, our majority of the built prototypes get approved. The industrial grounds have enough room for prototyping assembly.