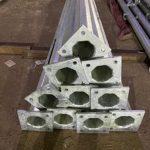

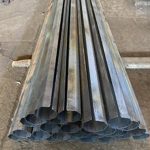

Octagonal Poles

The purpose of octagonal poles is to securely illuminate residential areas along with commercial and industrial locations. The steel plates are press shaped and longitudinally welded to create steel poles with octagonal sides.

The manufacturing process of octagonal poles includes these 6 steps:

- Cutting to Length

- Trapezium Cutting

- Longitudinal Folding

- Longitudinal Welding

- Welded Base Plate, and Brackets to carry luminaries / Flood Lights

- All steel parts are hot dip galvanized.

Mr. Rajesh Ummat : 919215598965

Description

Continuous welding ensures uniform deposition at all points and deep penetration welding.

1. Dimension

- Height:(5 to 12)mtr

- External Diameter

- Min. at top : 60mm

- Max. at bottom : on request

2. Material Standards

- IS : 5986, (FE -510)

- EN 10027 -1-1992

- ASTM – A656 (GR-60)

3. Galvanisation

- IS : 2629

- EN- 10027 – 1 – 1992

- ASTM – A123 / A123M-02